Redesigning (Reverse Engineering)

Redesigning (Reverse Engineering) is also called Reengineering or return engineering. It is reconstruction and analysis of a system structure for the purpose of deducing its technological principle and its reproduction at higher application level. The reverse-engineering process involves measuring an object and then reconstructing it as a 3D model. Reverse engineering therefore implies creating a mathematical model (with drawings etc.) of an existing physical object.

The method of return engineering is one of the most powerful ways to reduce time and expenses while working out a mathematical model, and in some cases a unique possibility of deducing design decisions or a technological principle from a unique end product on which the technical documentation is no longer available or does not exist. The mathematical model can be obtained by taking apart a physical master model or product-sample or obsolete drawings.

The process of return engineering consists of the following stages:

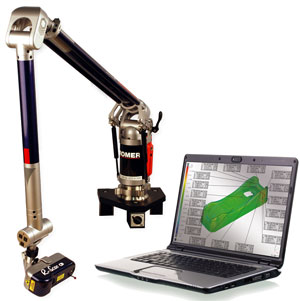

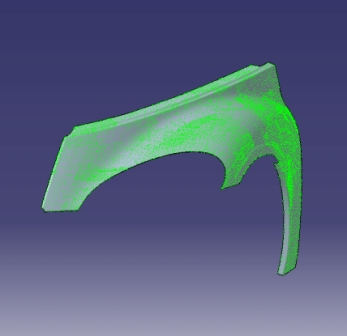

• measuring and analyzing a detail (using 3D scanning technologies to obtain point clouds or sizing it up using other tools);

• analyzing point cloud and building up base surfaces;

• control of base surfaces;

• building up mathematical model;

• control of mathematical model and its adjustment or update (if necessary);

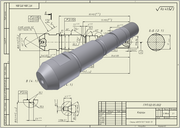

• carrying out working drawings (optional);

• delivery of mathematical model and drawings to the customer in any desirable format: STEP, STP, X_T, PRT, IGES.

If you have a detail, but do not have its mathematical model and working drawings - contact us, we will be happy to help!

QUALITY AND ACCURACY